Other related articles

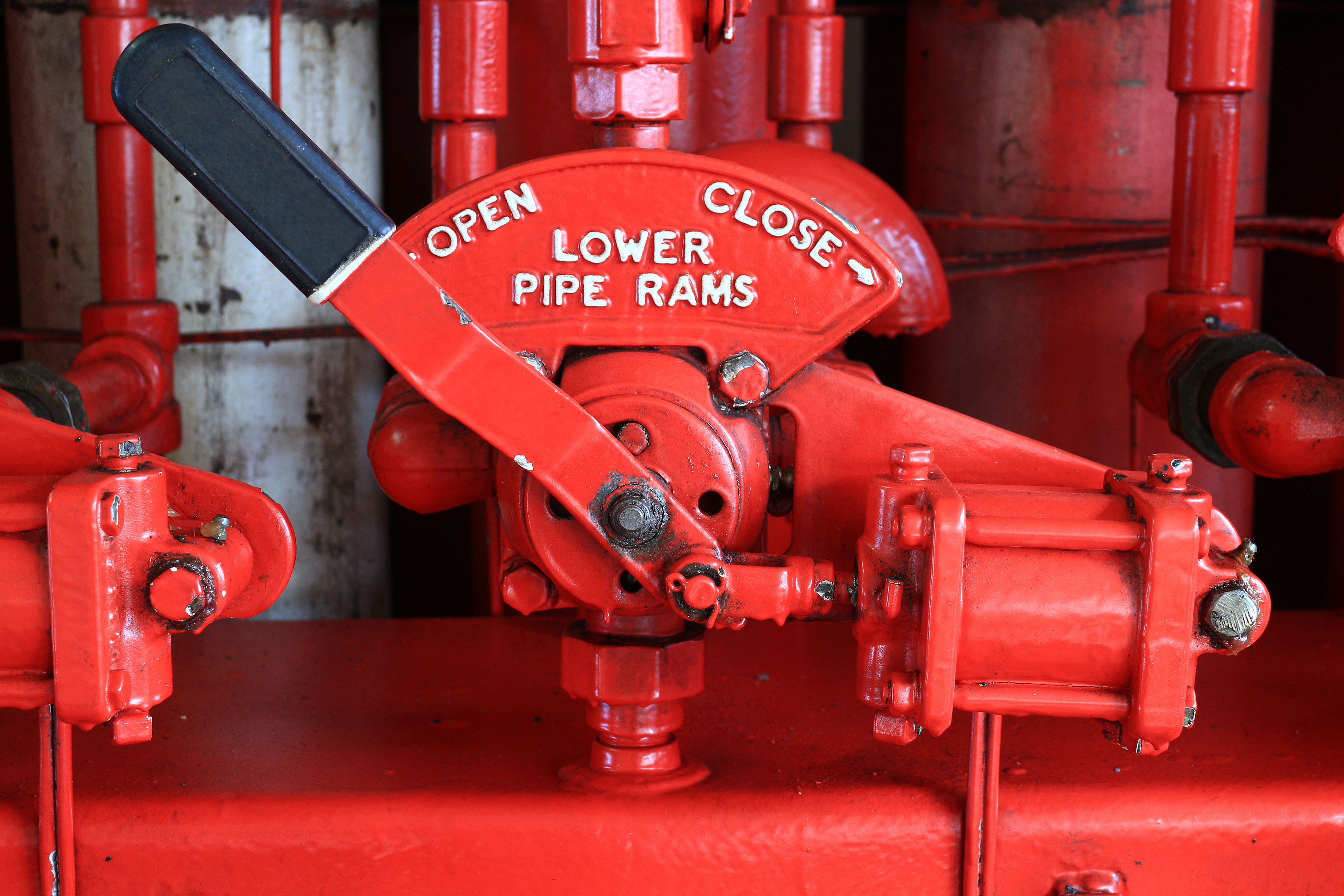

The Surprising Significance of Rocks Coiled Tubing BOP (Blowout Preventer) Bell 206 Helicopter

The Use of Bulldozers in Different Projects

What is a Bulldozer? Bulldozer is a heavy earth moving equipment that is used in industries and grading applications, including construction, mining, demolition, landscaping, oil and gas fields, and agriculture work. The Bulldozer pushing numerous quantities of materials such as snow, soil, rubble, debris and release materials. Which one is most commonly used in the industry? In the oil and gas industry, the most commonly used bulldozers are typically Caterpillar models, particularly the Caterpillar D6, D8 and D9. These are favored due to their power, durability, and ability to handle the rugged terrain often found in oil and gas fields. Caterpillar D6, is a well-known and widely used model, though it is generally considered a medium-sized bulldozer compared to the D8 and D9 models. The D6 can be used for tasks like grading, trenching, and maintaining access roads. Caterpillar D8: Known for its versatility and balance between power and maneuverability. It's used in a wide range of applications, including road building, land clearing, and site preparation in oil and gas fields. Caterpillar D9: This is a larger, more powerful model used for more demanding tasks, such as pushing large volumes of earth or rock. It's particularly useful in tougher environments where heavy-duty work is required.

The two examples below demonstrate that bulldozers are used for different tasks. Mini Dozer This mini dozer is ideal with resident projects due to it smaller size, which enables it to move in tight spaces with efficiency. It's usefull for sloping, grading, back filling, pushing snow, clearing land, working in any type of residential or confined commercial area. Crawler Dozer A crawler is similarly like a tractor, which provide a good traction and stop sinking into soft materials like debris or sand. Smaller crawlers serve as grading tractors in less demanding earthmoving, projects, which offering versatility and quality efficiency. And larger crawlers are designed for heavy duty applications, such as road construction and mining, where they move massive volumes of materials.

Select your Bulldozer BladesWhen selecting a bulldozer for a project at a worksite, it is essential to choose the right blade for the job. Why? Because choosing the right blade for the job is essential because the blade directly impacts the efficiency and effectiveness of the bulldozer in performing specific tasks. The blade's design determines how well it can push, dig, or move materials, affecting the quality of the work and the time it takes to complete the project. A blade suited to the material type and project requirements ensures optimal performance, reduces wear and tear on the equipment, and minimizes fuel consumption and operational costs.

Using the wrong blade can lead to inefficient work, potential damage to the equipment, and increased project time and costsHow to Choose the Best Bulldozer for Your Project? Here are some key factors to consider:

• The specific tasks the bulldozer will need to perform, • Assess the terrain where the bulldozer will operate, • The choice blade type, • Consider the engine power and the size of the bulldozer, • Confined spaces or urban areas, • Known for its durability and ease of maintenance, • Balance the cost of the bulldozer with the project's demands. Finding the right bulldozer for your project is crucial for success on the job site. Whether you need a machine for heavy-duty tasks or more specialized work, Ballycatter got bulldozers to meet your needs. With our range of high-quality equipment and commitment to customer satisfaction, you can trust Ballycatter to provide the reliable machinery that will help your project run smoothly. Let us equip you with the best tools to get the job done right. Written by: Ndeebom, MeenaaluBari Victor