Other related articles

Everything Planned Perfectly, Except for One Small Part... Crew Bus Service Rig (Workover Rig)

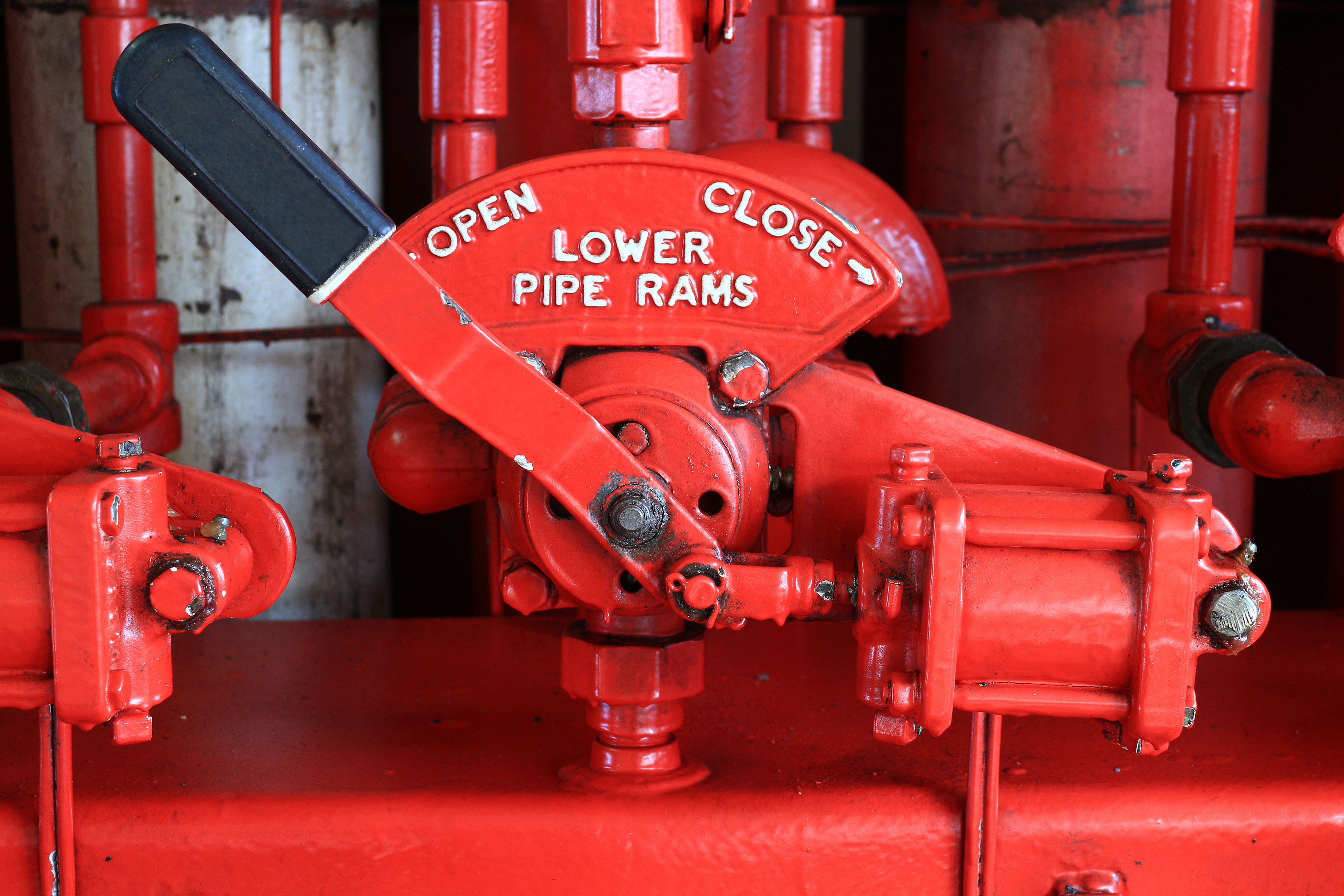

Drilling BOP (Blowout Preventer)

A drilling BOP (Blowout Preventer) is a specialized piece of equipment that is used to control the pressure and flow of fluids in a well during drilling operations. It is a critical safety device that is designed to prevent blowouts, which can cause fires, explosions, and environmental damage. A BOP typically consists of a series of valves, actuators, and rams that can be used to shut off the well in the event of an emergency.

The typical drilling BOP has several key components, including: • The control system: The control system of a BOP is the component that allows the operator to control the various valves, actuators, and rams that make up the BOP. It typically consists of a control console, a control panel, and a series of control lines that connect the control system to the various components of the BOP. • The annular preventer: The annular preventer is a type of valve that is used to seal the wellbore around the drill string. It typically consists of a series of rams that can be closed to seal the wellbore in the event of an emergency. • The ram preventer: The ram preventer is a type of valve that is used to seal the wellbore around the drill string. It typically consists of a series of rams that can be closed to seal the wellbore in the event of an emergency. • The choke and kill lines: The choke and kill lines are a series of pipes that run from the control system to the various valves, actuators, and rams that make up the BOP. These lines are used to control the pressure and flow of fluids in the well.

The engineering specifications for a drilling BOP are: • Working pressure rating: typically from 2,000 to 15,000 psi • Size range: typically from 3 1/16" to 21 1/4" • Standard: API 16A (American Petroleum Institute)

A drilling BOP (Blowout Preventer) is a critical piece of equipment that is used to control the pressure and flow of fluids in a well during drilling operations. It is designed to prevent blowouts, which can cause fires, explosions, and environmental damage. A BOP typically consists of a series of valves, actuators, and rams that can be used to shut off the well in the event of an emergency. The BOP is controlled by a control system, and an operator can control the various valves, actuators, and rams that make up the BOP. The BOP is typically made of steel and is designed to be able to withstand the loads and stresses that are applied to it, as well as to resist wear and tear and corrosion over time. The BOP is an essential component of drilling operations, and it is critical to the safety of the crew.

You may also like

Image from https://www.researchgate.net/figure/Blowout-preventer-side-view-A-Drillstring-not-spaced-

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.