Other related articles

Hydraulic Cylinders Sand in my Valve! The Use of Bulldozers in Different Projects

The Pulling Tool that ALMOST Fit

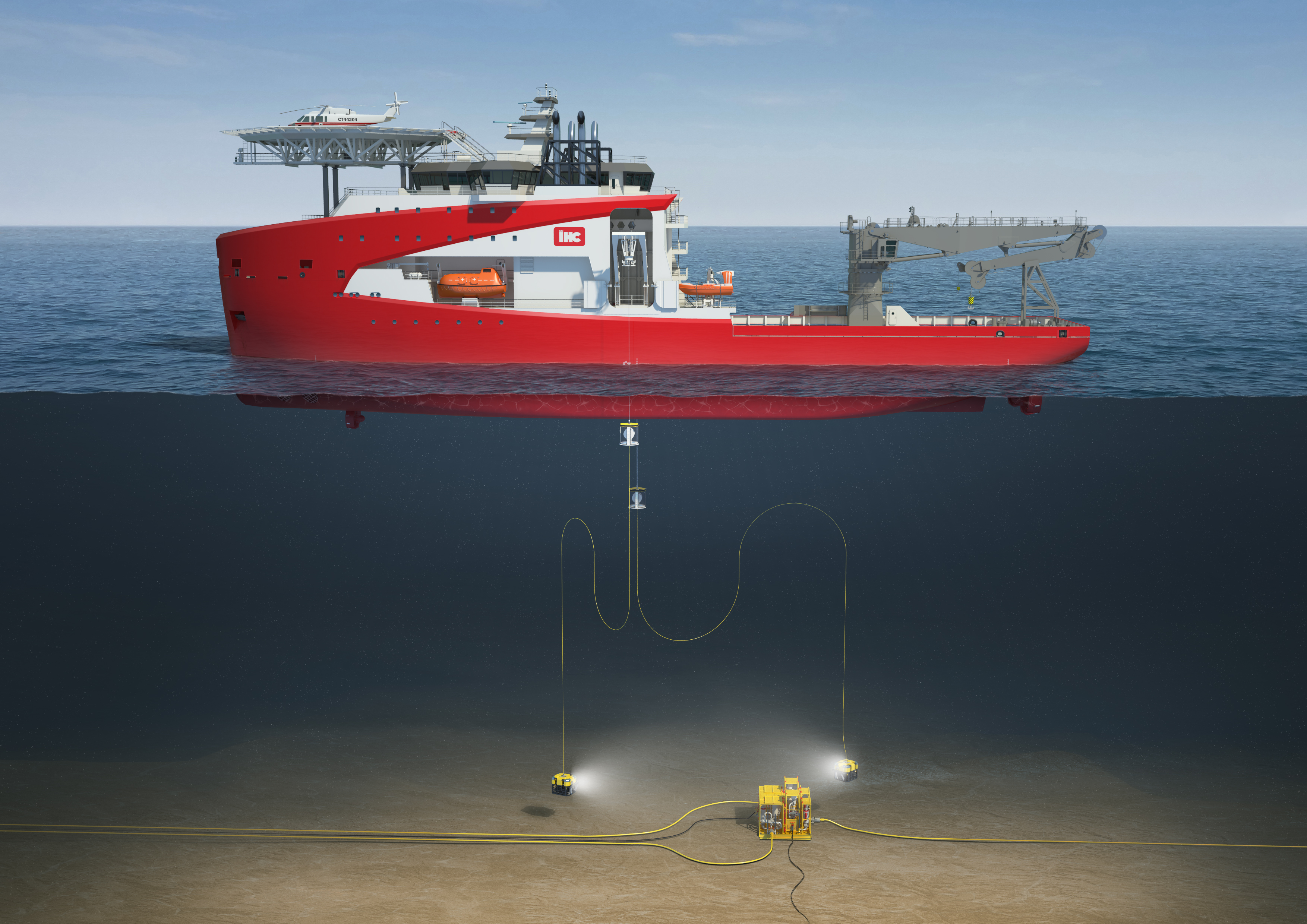

When you are planning a wireline job no detail is too small. I had planned a job in offshore Australia where the job was fairly simple - it was just pull gas lift valve out of the completion. It was a single valve installed many years ago and I just needed to pull the valve and set a dummy. I had reviewed the well file and the only thing that stood out was the lack of activity on these wells since the wells had been drilled there had been no workovers or well interventions completed after 20 years. As with most well interventions there was limited time to prepare, and this was a fairly straight forward job. Luckily the pulling tool was locally available, as well as the slickline crew (meaning they were mostly in the same country), and equipment. We needed a large bore kickover tool but this was in stock and available so it looked like it was going to be fairly easy this time. I lined up a supervisor who used to work on the production side on the same platform, so things were coming together nicely. The oil industry is really good at adopting a technology (once it is proven) and then applying it to solve issues specific to their specific environment. However, the industry is not so fast to adopt new ways of doing things which is reasonable considering the safety and financial risks involved in the business we are in. When cost estimating the first of any type of work in an asset or area, the actuals will almost always be higher than average, but as lessons are learned and the work becomes standardized, efficiencies appear that will drive costs down and increase asset value…but, you have to start somewhere. An extreme example of this would be pulling a gas lift dummy valve – probably one of the most common activities in a platform-based oil well, however, if it has not been done on a platform, asset, company, area, before, it can be met with a healthy amount of skepticism. This was a standard operation and all the pieces were coming together. I have always enjoyed using a GANTT chart and seeing what is on the critical path when planning a project execution. No-one wants to be on the critical path, but everyone will use every possible day they can get before becoming the long lead item. On this job the critical path was the availability of the slickline unit, so there was time to look at other aspects. This gave time to have a thorough review of the program.

One of the discussions on tool selection was around the benefits of adding a valve catcher to the pulling tool. The valve catcher is basically a bull-nose added to the bottom of the kickover tool that, in the event the gas lift valve falls off the pulling tool, it will be fall into the backside of the bullnose and continue to be pulled out of the well with the pulling tool. Since the well went horizontal, a good argument was made that if the tool dropped it would not be easy to fish it out. The item was added to the risk register, the program was updated, the equipment order and tool string diagrams updated, and all without any impact to the critical path. The economics of pulling a gas lift dummy and adding a live valve is not complex and typically can be calculated on a napkin as long as you know the cost of the job, the expected incremental from gas lifting the well, and the net profit per bbl sold (I should note that this can also get complex if you are not on an offshore platform with basically fixed costs and a ready supply of high pressure gas). This made this job an easy sell and should help encourage more well intervention (and drilling) activity in this asset – always good to start small and simple.

I haven’t seen this in any project management books, but...The service company was busy with a lot of activities, and we were a new customer so not really a big fish for them, but they were responsive and cooperative in planning the job. I have found that this is one of the key variables in how a job is going to go…I haven’t figured out how to put it into a formula, but if people get along well and work together in the planning phase, most times the execution goes slick, and conversely, if it is painful to do the planning part, the execution is going to be worse. I haven’t seen this in any project management books, but I have a good correlation when I “trust my gut” when trying to get something done – if my intuition tells me there is tension between people, or stress, or focused on something else, no amount of process will save the project. This may not be popular in the project management world, but I believe having a competent, focused, and friendly team can solve a lot of issues.

Pull Harder!

As I had suspected from the planning phase, the execution went really well. Mobilization to the platform, rig-up, working with production, was all proceeding as expected. Even running into this old well for the first time had no issues (lots of little issues solved by teamwork, no doubt) and latching the gas lift valve also went well…but then, the valve wouldn’t pull. “What do you mean, it won’t pull?”, I asked, thinking the valve had welded itself into the side pocket mandrel after so many years. “No, it jarred out of the pocket no problem, we went about three feet and just hung up”… Can’t go up, can’t go down, no movement at all – not what you want to hear from a slickline supervisor! What was going on here? Time to review everything (middle of the night, of course) and then I see it… What length extension is the valve catcher? Oh no! - it is the standard length, not for the large bore valve we have… The gas lift valve had pulled from the sidepocket mandrel, and pulled back into the tubing and the base of the valve landed in the valve catcher, but as the diameter reduced going from the SPM to regular tubing, the valve was too long for the catch tool and could not fit slick inside the carrier. The result – a tool string wedged in the top of the mandrel! Working as part of a slickline crew is busy. To keep the cost of slicklining low, slickline supervisors, operators, helpers, and crane drivers are all expected to be flexible and work together to get the job done. An experienced slickline operator can “feel” the situation downhole which an untrained person cannot see by watching the weight indicator or depth counter. On this job we had the benefit of top people and a real team environment, and with the clear direction to “Pull Harder!”, the tool string started to come up the hole. By finding the right balance between jarring to move to toolstring up without getting too “rammy” and breaking something, the slickliners managed to keep the tool moving to surface. After getting wedged, and unable to jar down or shear off, the option of pulling until something comes actually worked. I should emphasize that a detailed engineering analysis of the options was considered (including dropping a go devil and upgrading to braided line or coiled tubing), but it was the subtle skill of the slickline crew that coaxed a jammed toolstring through the completion and x-mas tree. When the string got to surface the pulling tool was in relatively good shape but the gas lift valve was bent totally out of shape (but still looked like a valve). The dummy was pulled and a new valve was installed (we still ran a tool catcher on the install, but the assembly was made up with the valve to make sure we had the right size – something I like to do now whenever I can), and if you look at the total job cost it was a bit of a trainwreck. It is hard to call a project where you double the cost (it took time to get the valve out) a success, but, even at the increased cost, the project was still economic and paved the way for many more interventions and drilling campaigns for the next fifteen years. I admit it was a stressful time when the toolstring was stuck like duck and there were limited options which all involved significant cost and risk escalation, but keeping focused on what the project goal was, and not falling into playing the blame game kept a positive atmosphere where everyone had a chance to contribute ideas and solutions. This same team stayed together for many more well interventions and we surely had more challenges, but everyone knew it was about solving issues rather than building a file against a service provider which helped use the power of a positive work environment to give real, tangible business results.

You may also like

Https://www.youtube.com/watch?v=CSOGiVLQ7DI

Https://www.youtube.com/watch?v=LRmvgNfmBAE

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.